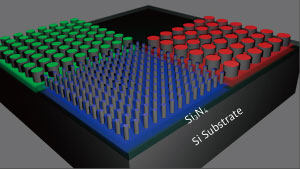

A schematic of the surface the team created featuring tiny silicon nanostructures.

© 2018 A*STAR Institute of Materials Research and Engineering

The detail in color images is limited by the size of pixel that can be printed. Recent advances in nanotechnology have opened the possibility of printing at incredible resolutions of around 100,000 dots per inch, by using metallic nanostructures that resonate in response to incident light. However, the colors that these systems produce are limited, and cannot fill the standard Red Green Blue (sRGB) palette used in most devices and the Internet.

Now, a team including Joel Yang, Arseniy Kuznetsov and Zhaogang Dong at the A*STAR Institute of Materials Research and Engineering (IMRE), and Data Storage Institute (DSI) have produced a new printing system with nanostructures made from silicon, achieving a spread of colors even wider than sRGB.

“We have been working on ultra-high resolution color printing for the past five years, and now we have solved the problem of limited color saturation,” says Yang. Unlike previous efforts with nanostructures made from precious metals such as silver and gold, the team used silicon, which is cheap, readily compatible with existing electronics, and has useful optical properties.

The researchers used electron-beam lithography and reactive-ion etching to produce tiny silicon disks, 130 nanometers high, on a 70-nanometer silicon nitride layer. The nitride acts as an ‘anti-reflective’ coating, effectively tricking the incident light into behaving as if it is not there and the nanodisks are floating in free space.

“An important requirement for ideal color reflection is to meet Kerker conditions, where incident light excites magnetic and electric dipoles in a silicon particle in such a way that the particle scatters light entirely in one direction,” explains Yang. “In free space, the uniform surroundings of the particle allow Kerker conditions to be met. A substrate will generally break spatial symmetry, but if the substrate does not reflect, the situation is equivalent to light propagating through free space.”

Yang, Dong and co-workers experimented with several different sizes and spacings of nanodisks, as well as nanorings, on their substrate, until they were able to achieve high-resolution images with over 120 per cent of the sRGB color palette — the best quality color from any nanostructure system of this resolution. They demonstrated the system by accurately reproducing a print of Wassily Kandinsky’s famous painting Murnau Street with Women.

The IMRE and DSI team involved in this research, standing in front of their reproduction of Kandinsky’s Murnau Street with Women.

© 2018 A*STAR Institute of Materials Research and Engineering

Yang and Dong are hopeful that their new design for nanostructure printing could eventually be accessible to everyone via a desktop device, and could also have applications in miniaturized displays, data storage and security prints for identifying counterfeits.

The A*STAR-affiliated researchers contributing to this research are from the Institute of Materials Research and Engineering and the Data Storage Institute.